AFM: High-Quality Finishing for Industrial 3D Printing

As 3D printers become more ubiquitous, the question manufacturers are trying to answer is not ‘how do we incorporated industrial 3D printing?’ but ‘how do we incorporate industrial 3D printing better than our competitors?’ Whether your application involves additive layer manufacturing (ALM) or laser sintering, the key that can set your

product above the rest is finishing.

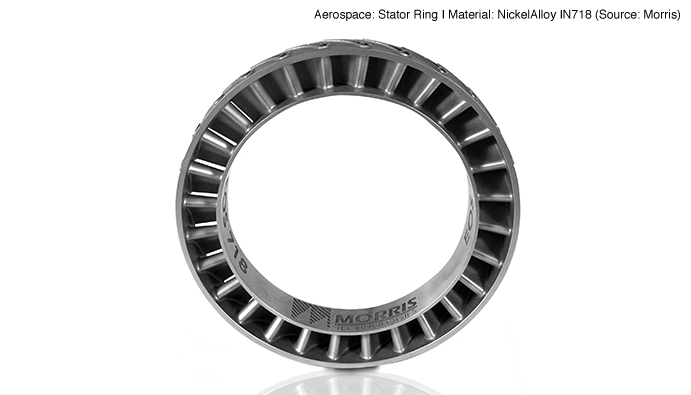

Products created through ALM or laser sintering processes, especially if you’re working in metals, come through with rough, imprecise edges and corners that lower the quality and usability of the product. Hand-finishing them to create the required surface tolerances for maximal efficiency requires highly trained (and expensive) personnel and loads of time. Plus, complex items may contain internal chambers that are difficult or impossible to reach.

EXTRUDE HONE’s patented abrasive flow machining (AFM) technologies offer two solutions to all the problems of hand- polishing. They can bring down manufacturing costs, speed up delivery times, and provide the high-quality, high-tolerance finishes that you need and your customers deserve.

polishing. They can bring down manufacturing costs, speed up delivery times, and provide the high-quality, high-tolerance finishes that you need and your customers deserve.

With the AFM process, a viscoelastic polymer is impregnated with abrasives and then pumped through a workpiece. As the polymer flows through, the abrasives within it polish the piece’s internal surfaces, even in the chambers where fingers can’t reach. The entire process is automatic, repeatable, and predictable, and it can be “flow tuned” to meet specific strength and tolerance needs: temperature, pressure, abrasive type and size, and speed of the polymer are customizable.

AFM also removes stress concentration points, like scratches and sharp corners, thereby increasing fatigue strength much more quickly and consistently than with traditional polishing operations. Our tests have also revealed that AFM adds a small compressive residual stress to machined surfaces, further increasing fatigue strength.

The high-quality, high-speed results from AFM give you a new freedom of design for ALM or laser-sintered products, along with fewer product failures and their associated costs. If your production line includes industrial 3D printing or other additive layer technologies, EXTRUDE HONE can offer not only the machines to help you create a high-quality finish, but the expertise and experience to provide advice at the design stage and the facilities to provide contract machining or turnkey solutions in your factory.

EXTRUDE HONE’s electrochemical finishing can also offer you even more quality and flexibility for your 3D manufactured products. We are in the process of developing a new and exciting finishing process. More information about this new finishing technology and how it can help you create higher-quality parts with better accuracy and repeatability will be coming soon.

Our partner in 3D printing: EOS e-Manufacturing Solutions. .